Future-Proof Production in Focus

Labotek Showcases Energy-Efficient Innovations at K´2025

With a comprehensive portfolio of technological innovations, Labotek will present pioneering solutions for resource-efficient, flexible, and cost-effective plastics processing at this year’s K-Messe in Düsseldorf.

Key highlights include new drying and control systems, smart energy concepts such as External Heat Recovery (EHR), and digital tools for process optimization.

“In a time when efficiency, sustainability, and quality set the pace, our technologies help position production processes to be both economically viable and future-proof,” emphasize Labotek A.S CEO Thomas Ringheim.

NEW PRODUCT LAUNCH

MDS Balance Drydose – Dosing and Drying in One

MDS Balance Drydose – Dosing and Drying in One

Labotek and Movacolor have joined forces and developed an innovative solution to address the need for drying additives. The result is the MDS Balance Drydose. This new system is a one-of-a-kind system that combines efficient material drying and precise additive dosing in a single, compact unit.

The Drydose accommodates the upward trend of drying additives due to increasing quality requirements, materials of biological origin, specialty engineered plastics, and the need to further reduce quality risks.

By drying materials directly within the dosing unit at the machine inlet, the Drydose ensures optimal moisture control and removes the need for additional drying equipment. This integrated approach enhances product consistency, reduces waste and energy consumption, and improves overall production efficiency.

„After installing the MDS Balance Drydose, our previous streaking problems when adding additives are simply gone!“

Bernd Wilming, Plant Manager, agathon GmbH

The MDS Balance Drydose will be presented for the first time at K´25, marking its official debut.

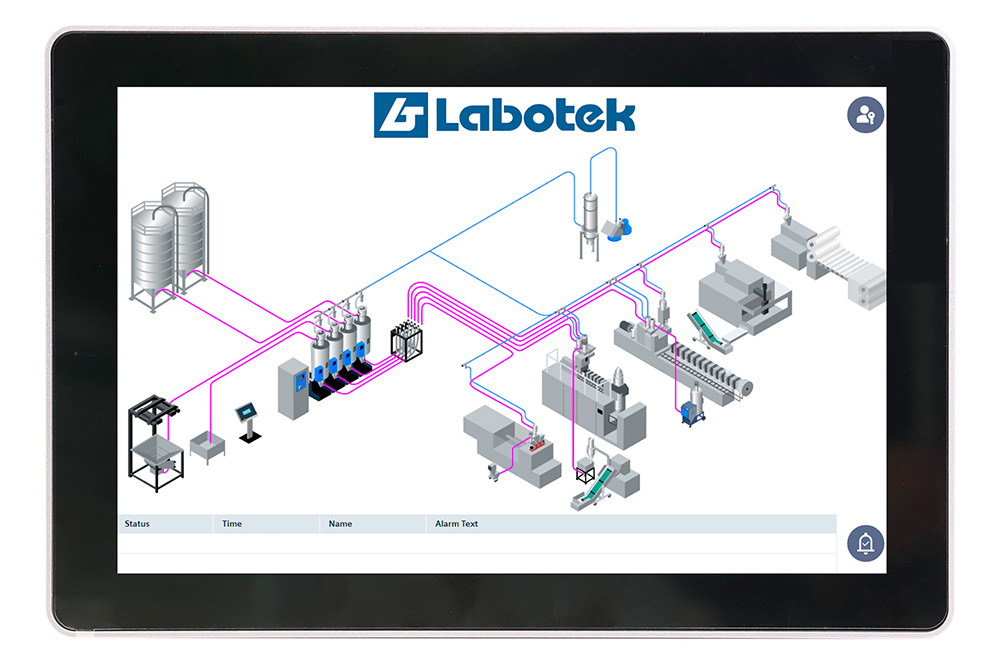

Labotek Control Concept – Smart, Modular, Scalable

Our new control platform is designed to simplify setup, improve flexibility, and support future expansions of Labotek systems. It’s an innovation that brings together drying, conveying, and heat recovery into one seamless, user-friendly environment.

Key features include:

- Designed for DFD (Desiccant Flex Dryer), DH (Drying Hopper), SVS (Scanning Vacuum Station), and EHR (External Heat Recovery) modules

- Central 10-inch touch panel integrated into the DFD

- Supports up to 14 local units (each with their own 7-inch panel)

- Modules interconnected via Profi-Net for seamless communication

- Cascading network layout reduces cabling and simplifies integration

- SVRs are connected through dedicated control units with eight outputs

- Load cells can be integrated beneath hoppers for weight monitoring (central and local control)

- Modular setup allows plug-and-play expansion via Profi-Net cables

- Compatible with Labo-Net, which as standard can function as the master control across up to 62/93 stations, including :

- 3 DFD units

- 5 SVS stations

- 40 DH bins

With the new control concept, EHR can also be operated as a stand-alone unit – flexible and manufacturer-independent.

LCD – Compact Compressed Air Dryer

The new Labotek LCD is developed for smaller-scale drying applications, offering a compact, energy-conscious solution where ultra-low residual moisture is not required. It’s ideal for injection molding setups that prioritize flexibility and efficiency.

Highlights:

- For applications with up to 15L material volume, LCD is more energy-efficient than traditional dry air dryers

- Offered in 5L and 15L container sizes only – optimized for energy performance

- Stainless steel interior and brushed stainless steel exterior

- Ideal for smaller injection molding machines where space and efficiency matter

- For larger volumes, we recommend LRD, DDM, or DMR dryers

- Equipped with intuitive microprocessor control, editable material presets

- Airflow adapts automatically to throughput and material type

- Integrated over-drying protection minimizes energy waste

- Includes Android app for mobile configuration and remote adjustments

BOTTLE-2-BOTTLE

Continuous PET Crystallization

Our new system supports the bottle-2-bottle PET recycling process with reliable crystallization of amorphous flakes. Engineered for compact layout and process stability, this system ensures reliable, energy-efficient performance in circular economy operations.

GRAVI-DRYER®

Proven and Evolving

The Gravi-Dryer® continues to be a cornerstone in energy-efficient and traceable plastics drying. Adaptive drying times, minimal over-drying risk, and full documentation make this system a favorite across the automotive and pharmaceutical industries.

External Heat Recovery

The EHR system from Labotek enables significant energy savings by recovering excess heat from other processes (e.g., compressor cooling systems):

-

Uses hot water to heat process air in Labotek dryers via high-efficiency air-to-water heat exchangers

-

Depending on temperature and flow, electricity savings up to 85% are achievable

-

Seamless integration with Labo-Net or new control platform

-

With the introduction of our new control concept, EHR can also be operated as a stand-alone unit – flexible and manufacturer-independent.