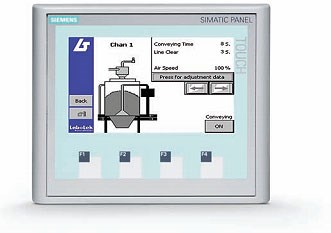

Labo-Scan Touch Screen Control

Operation of the control is extremely easy; a user-friendly interface via a 6” touch screen enables automatic control of conveying of raw materials up to 32 stations.

The control is able to handle our energy-saving frequency-controlled vacuum station as standard.

Suction time, line clearing time, suction address and air speed frequency are adjusted directly on the screen, either via keyboard pad or drop-down boxes. The operator can scroll between station selections as required. The Labo-Scan control has built-in control of the suction address, where a pneumatic slide valve under a drying hopper is operated, securing a safe and self-cleaning conveying cycle.

Huge energy savings may be obtained through our series of frequency inverters.

The Labo-Scan Series offers…

• Significant energy savings via frequency-controlled blower

• 6” Touch Screen & PLC from Siemens

• Flexible setup for great visual appearance

• Full control of all parameters for each station

• Ease of use, no need for special training

• Personalized descriptive texts and plain alarm texts

Comprehensive 3-year warranty

The Labo-Scan controls are prepared for a number of options.

Labo-Scan II

Up to 50 stations and 7” touch screen.

Delivery from March 2023.