control

Labo-Scan

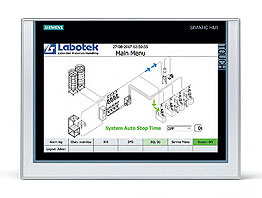

The Labo-Scan Touch Screen Control series takes full control of materials handling requirements. Operation of the control is extremely easy, a user-friendly interface via a 6” touch screen enables automatic control of conveying of raw materials up to 32 stations.

Labo-Scan II: Up to 50 stations and 7” touch screen.

Labo-Net

Labotek Labo-Net series takes full control of all materials handling requirements. The Labo-Net uses network communication between system components via the well-known, flexible and very reliable AS-Interface & Siemens Profi Net.

Labo-Net SQL

Safe & easy-to-use SQL database server directly in the PLC system, eliminating the usual tackle of Windows based software updates and virus protection software. Standard web browser tool for access to relevant process data from the drying and conveying system.