Efficient Air Cooling

New drying technology: Efficient Air Cooling - EAC

Together with battenfeld-cincinnati, Labotek has developed a new drying technology - EAC (Efficient Air Cooling) – efficiently utilizing the hot air generated during the extrusion process. EAC is a cooling system in battenfeld-cincinnati’s pipe head. This unique drying system is designed for all pipe extrusion lines using EAC technology.

Delivery program

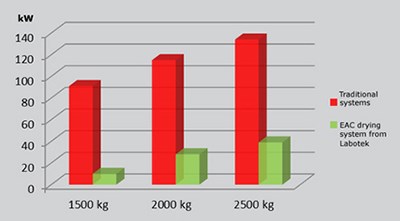

Labotek has 3 drying systems available as standard. Systems are designed for drying HD-PE for 1,500, 2,000 & 2,500 kg/h. The energy savings achievable when the EAC drying system is working to capacity are significant; a 1,500 kg/h HD-PE system needs only 11 kW, whereas a traditional system would use 91 kW *. This results in 88% energy saving.

The savings will return the investment rapidly.

Comprehensive 3-year warranty, excl. wear parts.

*) Energy consumption figures measured/calculated with Labotek dimensioning software for HD-PE with delta T=70K, specific heat capacity of 2.3 kJ/kg K, 0.2% initial moisture and all resign heating energy from EAC.

EAC Drying systems is a patent-pending technology