Precision meets moisture control

MDS Balanced Drydose

Drying and additive dosing in one compact unit. Maintain optimal moisture and consistent quality by drying directly at the machine inlet. The unit prevents costly defects, such as splay, streaking, and structural weaknesses, by stopping hydrolysis

at its source.

Efficient drying

Dry and condition materials close to the machine

inlet, minimizing heat loss and moisture reabsorption. Effectively dry material within hours (e.g. ABS in 2 hours).

Consistent product quality

Maintain optimal moisture levels throughout processing to prevent defects like hydrolysis, degradation, and surface flaws – ensuring superior mechanical and physical properties in end products.

Working principle

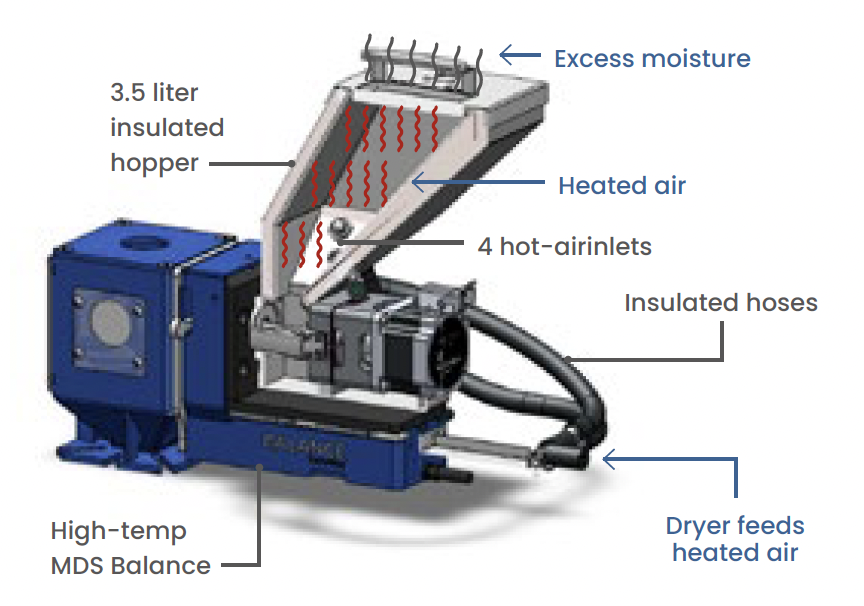

- The compressed air dryer supplies heated air through insulated hoses directly to the MDS Balance hopper.

- Material near the dosing cylinder/auger is also dried, minimizing the risk of moisture reabsorption.

- The hopper is equipped with four hot-air inlets and full insulation to ensure consistent drying and maintain optimal moisture levels.

- Excess moisture is safely released via the hopper lid.